Tractor-pulled compost turners - CMC ST 350

Compost Systems GmbH

Benefits using a CMC ST compost turner:

- Smooth operation of the rotor

- Fresh windrows in particular separate the wheat from the chaff.

Conical tunnel

The rotor hood opens to the rear to ensure free ejection of the material without obstruction and to loosely rebuild a new windrow without compaction. The difference becomes clear, especially with longer raw materials such as hay, grass or straw.

Wear and tear

By carefully selecting the raw material for worn parts, we try to reduce operating costs. For particularly wear-intensive applications, we offer solutions with carbide tipping. We will be happy to advise you on the best options for your application based on our many years of experience.

Construction and statics

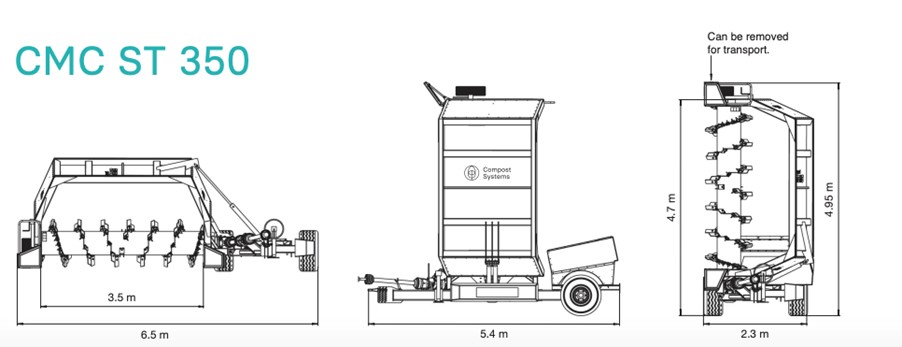

Thanks to modern 3D design technology and our more than 30 years of experience in building compost turners, we see ourselves in the role of solution leader in the industry. The steadily increasing engine sizes of tractors, which have almost doubled in the last 20 years in terms of power, pose another challenge to the technology, which under the motto bigger and stronger, unfortunately sometimes also means heavier. With smart, constructive solutions, Compost Systems strives for perfection. CMC ST 350

The powerful top-up for more throughput

A tractor-pulled compost turner with enormous power thanks to a 3.5 m rotor length and 4 m² windrow cross-section. Material quantities of up to 1,200 m³/h are no problem for this model. Tractor operation makes the CMC ST 350 a cost-effective, powerful solution for medium-sized composting plants.

The CMC ST 350 meets the strict criteria of Controlled Microbial Composting.